At Roccia, we’re rather proud of our reputation as renowned tile experts, and our team being some of the top dogs in the industry! Behind every intricate tile displayed in our showrooms is the smiling face of a professional, knowledgeable, and committed team who will go to the moon and back to make sure your home is as s-tile-ish as you deserve.

If you didn’t know already, Roccia has a dedicated engineering team who use the most ‘cutting- edge’ (literally) technology to make sure your tiles are perfect for any room. We focus on true interior design innovation, and make sure we really push the boat out on every project we get our hands on.

Want to learn more about what we do, what we use, and what truly goes into the crafting of a Roccia tile?

How Do We Craft the Perfect Tile?

The way that we make each tile depends on the type of material we are dealing with; from ceramic tiles to porcelain tiles, stone tiles and even glass tiles, our engineering team know what they are doing when it comes to any type of tile.

Firstly, the creative minds of our design team will explore the vast world of interior design to discover the hottest trends and timeless classics to ensure that you are super on-trend and get the product you have always dreamed of.

Our experienced in-house design squadron are like magpies – they like all things shiny and beautiful, and are sure to bring them back to the Roccia nest for you to buy. Our team will not only travel to the ends of the rainbow and all the way back to our showrooms with your new sparkly tiles, but they will plan and design the entire tiling process for you.

From strategising the design layout to cutting the tiles, and even organising someone to come and lay them, you don’t need to worry; Roccia has you covered.

Our engineering and design team also know the right people in the right places, and just like our project at Lancaster University where we teamed up with Norwest Holst, we love to get collaborative and pair up with some fantastic engineering minds.

We will then come around to your business or house and get down to business, transforming what was previously nothing more than a vision into a stunning reality.

What Do We Get Up To?

We all love tiles here at Roccia, but wait for it… we don’t just do tiles! Our creative minds can’t help but spill outside of the box, so we branch out and take on other applications such as bespoke panels, decorative screens, tailored mosaics and even tables.

Our bespoke mosaics are where we harness our elaborate cutting machine, our experienced engineering gurus, and the detailed eye of our design marvels, making sure that we create sheer precision and beauty each time. Coming in a variety of styles and colours, the option of a meshed back, and simple installation, our team live for turning your mosaic dream into reality.

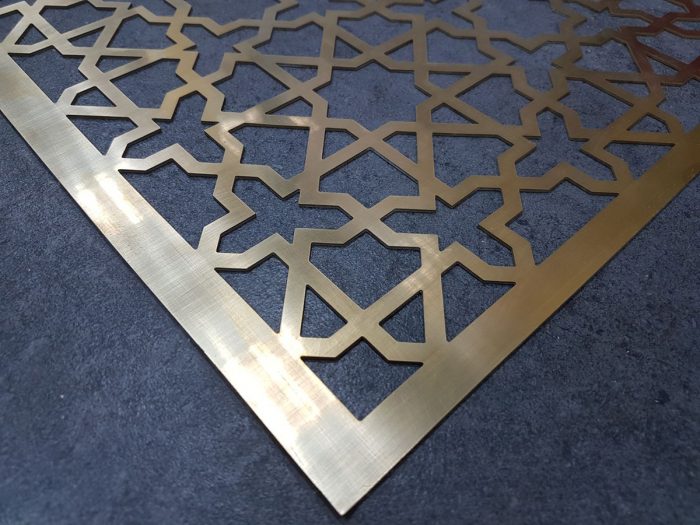

Another one of our fabulous engineered applications is our decorative screen, which we cut to any size or shape from any material you fancy. These make for a superb partition screen, a touch of artistic class on a wall, or even on the outside of a building!

We also dabble in bespoke panels, which can be a great eye-catching piece for any business; look at the one we created for Queens below.

What Do We Use?

Our waterjet machine is one of our pride and joys, giving us a sharp edge in the industry.

It cuts through almost any material, making it the perfect tool for architects, artists, sculptors, interior designers, and, of course, Roccia. It allows us to utilise the huge array of materials we offer and essentially make any material into a work of art.

So, what does this marvellous machine mean for Roccia?

The waterjet has the unique ability to cut intricate pieces at high speed without any breakage. Compared to other cutting tools in the industry, this one sure is a gem! It essentially uses a high velocity stream of ultra-high-pressured water, which is produced by an intensifier pump. This water pressure is so extreme that, believe it or not, it cuts our tiles just how we want.

Imagine a car wash with those fast, high pressure power washers. Now, times that pressure by around 30 and that’s what you get with our tile-cutting waterjet. This amazing piece of technology has the capability to cut any material, from 1mm to 120mm thick and up to a 4m by 2m profile.

Our engineering team adore new challenges, so if you have a new project in mind that would benefit from the use of our waterjet machine please get in touch with our in-house design team. You can call Roccia on 01772 382 716 or pop us an email at info@Waterjetcuttingdirect.co.uk, and we will get back to you as soon as we can.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.